Simpro Blog 2/4

Archived news, updates and ideas.

Vertical conveying of hygiene-critical bulk materials: a quick comparison

There are several options when it comes to vertical conveying of bulk material in a food-production line. Each has its merits. But some more than others. To simplify things, we’ve distilled all the differences down onto one handy chart*: Characteristic* Screw Conveyor Spiral Belt Conveyor Bucket Elevator MegaDumper® SS...

Bin-tipper integration: expertise that makes all the difference

One of the most common use-cases for Simpro bin-tippers is loading product into another machine or process. The next stage might be a compactor , composter , crusher , mixer, sorter, or something else; it might comply with any number of standards, or none. Yet it needs to be integrated seamlessly with our lifting equipment – not just physically – but also in terms of control...

Simpro Cart Tippers – how the range has been adapted for the USA market

After building an international reputation for reliable bin tippers for European wheelie bins, Simpro has released a completely adapted range of tippers specifically for the US market and is excited to be showcasing this with our distributor Solus Group at the Waste Expo in New Orleans next month. Due to the fundamental differences between waste carts used in the USA and the wheelie...

How long will a Simpro bin-tipper last?

I really need a bin-tipper. But it will have to be used outdoors, and I’m worried about corrosion. How long will it last? A very long time. Simpro has been manufacturing bin-tippers for three decades, mostly for use outdoors, in the rough-and-tumble waste industry, under the fierce Australasian sun. And most of these machines are still in use. Of course, you don’t have...

MegaDumper® Capacity Verification

Twenty years on, the huge capacity of the Simpro MegaDumper® still has the power to surprise. (Sorry Marek . Towels are in the locker room.) {cms_selflink href='megadumper'}

Manual handling - a quiet killer of the modern workplace

Bad news: Manual handling is responsible for an increasing share of workplace injuries. In Australia, new figures from Worksafe Victoria indicate that the proportion of ‘body stressing’ injuries rose to 37% in 2016 , even as the total number of injuries continued its decades-long decline. Similar trends have been reported elsewhere. This suggests that employers are still...

The best. Absolutely the best!

[The Multi-Tip] is the best thing I've made this school purchase, since I've been here... as far as compliance and relieving me of hard work, this is the best. Absolutely the best! Graham Hawkes - Caretaker - One Tree Hill College Graham Hawkes was pretty chuffed with his new Simpro bin tipper. In fact, he even agreed to go on camera for us...

EN 840 vs ANSI Z245.60 - the bitter battle of the MGBs

Everyone knows what a {cms_selflink page='240l-wheelie-bin' text='Mobile Garbage Bin'} is. These humble roadside receptacles go by all manner of names – MGBs, Wheelie Bins, Toters, Roll-out Carts, Trash Cans – but they all look something like this: Looks, however, can be deceiving. MGBs are designed to be lifted by {cms_selflink page='bin-lifters' text='machines'}, which means...

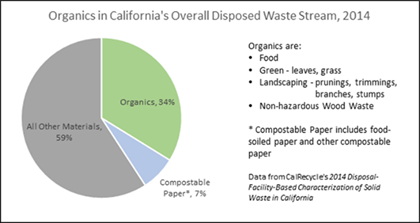

Throwing your apple core in the bin may be a thing of the past (if you're from California at least)

In October 2014 California legislated that all businesses generating more than 4 cubic yards of solid waste per week will have to recycle Organic Waste by 2019. The law is introduced incrementally from the 1 st of April 2016. Many in the western world are accustomed to the concept of recycling now; we all know that empty plastic containers should not go in the general waste bins don't we?...

Machinery Guarding: the engineer's lowdown

Standards for machinery guarding have been in law since 1844 , but you wouldn’t know it. Poorly-guarded machinery is still in use in workplaces everywhere – and each year claims a grisly toll of entanglement, crushing, amputation and dismemberment. Not to mention OSHA fines . Crushed hands and arms, severed fingers, blindness - the list of possible machinery-related...

Simpro closing and opening dates for 2016

As the year draws to a close, the team at Simpro Handling Equipment would like to take this opportunity to thank you for your custom and support throughout 2016, and to notify you of our end of year cut-off and closure dates. Our factory will be stopping production on Wednesday the 21 st of December 2016 . Over the holiday period materials handling equipment is given last priority by...

Press Release: Simpro acquires new Head Office and Manufacturing Facility

Simpro Handling Equipment Ltd, a New Zealand manufacturer of specialised materials handling equipment, is pleased to announce the acquisition of a new head office and manufacturing facility at 66 Rangi Road, Takanini, South Auckland. Managing Director Stephen Simmons founded Simpro in Auckland in 1986, manufacturing truck-mounted equipment for the waste industry. “This is an exciting...

Typical Skip Bin Sizes

Many Simpro customers are unsure which type of bin tipper will work with their skip bin or dumpster. This table provides a handy guide to common bin dimensions, and which bin tippers are suitable for each size. If in doubt, it is always best to use a tape measure to determine the height of your bin. Typical Skip Bin Sizes - Metric (Australia, New Zealand, Europe) Bin...

Seven industrial problems solved by Simpro bin tippers

Lifting and tipping bins has become one of the most common tasks in the modern workplace – and machines like the Dumpmaster are the best way to do it . Here’s a list of seven industrial problems solved by {cms_selflink page='bin-lifters' text='Simpro bin lifters'}. 1. Chemical Plant: tipping toxic, acidic, corrosive and explosive liquids Designing machinery for chemical...

Reliability Matters

It matters to us at Simpro anyway. Here’s why. Underneath this paragraph is a picture of a typical solid waste processing facility. It is equipped with a Dumpmaster hydraulic bin tipper from Simpro Handling Equipment, and provides a very important service to the communities nearby. But there is more to the story. If we zoom out a little, we see that this facility is on an...

The world’s first air-powered PL(d)/Cat3 bin tipping machine

There are not many options when you need a 250kg capacity bin-tipping machine that can operate in an explosive environment. And have variable speed. Oh, and have a locking door and safety system compliant with Performance Level ‘d’ . In fact, there’s only one. Sorry, Performance Level ‘d’? Performance Level ‘d’ (also known as Cat3) is the...

Made in New Zealand

Although Simpro has a global supply chain, our highest-volume products are still manufactured in Auckland, New Zealand . In a globalised world, it may seem incongruous to manufacture machinery in an isolated first-world nation whose largest exports are milk and tourism . But we’ve stayed in New Zealand for good reasons: Like many companies based ‘Down Under’, our...

Simpro bin tippers at Recycling 2016 in Holland

Simpro bin lifting and tipping machinery was on display last week at Recycling 2016 , an annual trade fair held in the South Holland town of Gorinchem . The expo was attended by representatives of the recycling and waste management industry from around Western Europe, as well as regulators and government bodies. Our Dutch agents Van Randwijk had both a Dumpmaster and a Multi-Tip on...

The hazards of implementing AS/NZS 4024:2014

An understanding of safety standards is essential for owners or purchasers of workplace machinery. Introduction Companies in Australia and New Zealand are required by law to provide a safe workplace for their staff, including ensuring that all new and existing machinery is safe for staff to operate. This requirement is set out by Workplace Health and Safety legislation in both...

Where is the Quikstak S-Series made?

I like the look of the new Quikstak S-Series . But are they made in New Zealand like the old ones? No, they aren’t. They are made in China. Why is that? We have manufactured Quikstak pallet stackers to the highest quality standards in NZ since 1994. In recent years, with new quality and safety standards emerging, it became clear it was time to overhaul the Quikstak design....