Simpro Blog 4/4

Archived news, updates and ideas.

Mark has a big job to do

Luckily, Mark also has a Simpro MegaDumper , and those can handle even the biggest jobs – we’ve got video to prove it!

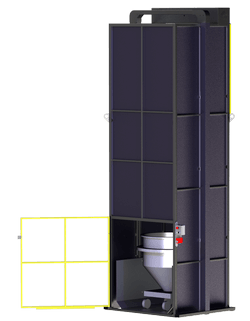

Simpro Hylifta helps out at Clariant New Zealand

When specialist chemicals company Clariant New Zealand needed a means of transferring product batches weighing up to 500kg between floors at their Albany facility, they chose a Hylifta Materials Handling Elevator from Simpro Handling Equipment. The custom-engineered high-capacity elevator was commissioned on 9 May and includes a suite of features to ensure the highest levels of...

Introducing: Dumpmaster Variable Speed Drive!

Simpro has always been committed to ‘continuous improvement’. We are always looking for ways to make our products better – even products like the Dumpmaster , which has been a market leader for two decades. So we are pleased to introduce our latest innovation, developed on customer request: Variable Speed Drive. A VSD unit with ‘joystick’ controller gives the operator...

The Cost of Back Injuries

Injuries to the back are one of the most prevalent and costly work-related musculoskeletal disorders in workplaces worldwide. By investing in well-designed bin lifting equipment, employers can significantly reduce the risk of injury to their staff and can potentially save not only themselves, but the country many times the value of the initial machinery investment. There is anecdotal and...

Solar Success!

An Auckland supermarket is using a Multi-Tip to empty their wheelie bins, and recharging it with the power of the sun. The Multi-Tip uses a 12v battery system that can be charged either by the standard mains charging socket or by 'trickle charge' from the solar panel mounted above the machine. Even on cloudy days the solar panel usually keeps up with usage, meaning the machine almost...

Solution for the Sallies

After a recent audit the Salvation Army Family Store in Hamilton NZ has installed a new Simpro bin tipper to eliminate the possibility of back strain or other injuries while emptying bins of waste. Every week the store generates up to 20 bins of waste material from its recycling program - which until recently had to be emptied by hand. Manually emptying the bins into a skip was difficult...

Modified swivel wheel for Quikstak

A packaging manufacture was recently faced with the difficulty of taking 3.5m long rolls down the aisles of storage on their pallet trucks. A {cms_selflink page='quikstak-smart-stacker'} with front swiveling castors provided the perfect solution, allowing users to easily roll the stacker and the load in any direction. The castors had a directional lock allowing users to fix one of the...

Improve the way you move!

Recently a care home in Wellington investigated ways to improve the handling of waste to help them eliminate the risk of back and shoulder injuries to staff. Like many aged care providers, the home has a diverse workforce, with some taller staff and some shorter staff. Not everyone could lift wheelie bins full of rubbish. The home purchased an Ezi-MT bin tipper which has been a great...